GEN II Platform

Automated, miniaturized, cell-free DNA production

Introducing the GEN II Cell Free DNA Production Platform

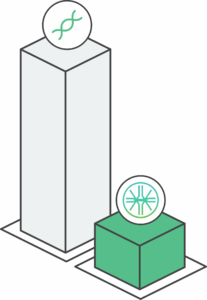

Elegen’s GEN II Platform combines our innovative microfluidic DNA synthesizer with our patented cell-free cloning technology. This system fully automates the production of high-quality linear dsDNA with exceptional speed, efficiency, and low cost.

The platform spans all stages of cell-free DNA production—from oligonucleotide synthesis, to fragment assembly, to construction of full-length constructs serving as the foundation of our three ENFINIA™ product lines: Linear DNA, IVT Ready DNA, and Plasmid DNA.

STEP ONE

Oligonucleotide Production

Our oligo synthesizer uses a proprietary microfluidic chip to simultaneously produce thousands of unique single-stranded DNA oligos using a split-pool synthesis approach.

Integrated positional encoding enables precise tracking of each oligo for continuous quality control throughout the process.

At the end of a synthesis run, oligos are sorted by customer order and dispensed into one or more wells of a microplate.

By miniaturizing DNA synthesis and supporting multiple orders on a single chip, this technology delivers lower operating costs, a compact instrument footprint, and significantly reduced waste.

STEP TWO

Long, Linear DNA Synthesis

Plates of oligos are loaded onto robotic workcells that perform proprietary, in vitro, methods to assemble, clone and purify long linear DNA constructs that cover a wide range of sequence complexity – all without ever touching cells.

The end result is DNA constructed with 99.999% per base accuracy at exceptional speed and at a fraction of the cost to synthesize and clone DNA in cells.

STEP THREE

Sequence-perfect DNA products

The resulting sequence-perfect constructs underpin every product in the ENFINIA portfolio.

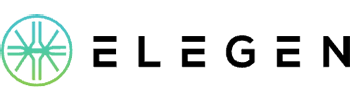

Cutting Costs and Boosting Efficiency

Conventional DNA synthesis requires factories full of bioreactors to support bacterial fermentation for large-scale DNA synthesis. By moving to a fully cell-free workflow, Elegen shrinks the entire process, reduces reagent consumption, and dramatically improves efficiency. This compact, efficient approach delivers unprecedented manufacturing agility for Elegen’s differentiated products, reduces costs for our customers, and reinforces our commitment to sustainable practices.

AI Driven

Powered by a proprietary LLM that converts customer sequences into production protocols encompassing oligo design, reagent procurement, robotic operation, and production scheduling – all while learning and optimizing in real time.

Capital-efficient

Capable of generating >10X more genes per square foot in comparison to the cell-based factories required by market-leading gene synthesis suppliers.

Low-cost operation

Supported by just two engineers, the entire process — from synthesis to amplification — is miniaturized, using a fraction of the chemicals used in cell-based approaches, significantly reducing the carbon emissions associated with every order.